MECHANICAL TEST

LABORATORY

The mechanical testing laboratory carries out activities aimed at the verification, control, approval and qualification of materials, products, machines, industrial components, mechanical components, electrical equipment and packaging.

VERIFY

CHECK

APPROVAL

QUALIFICATION

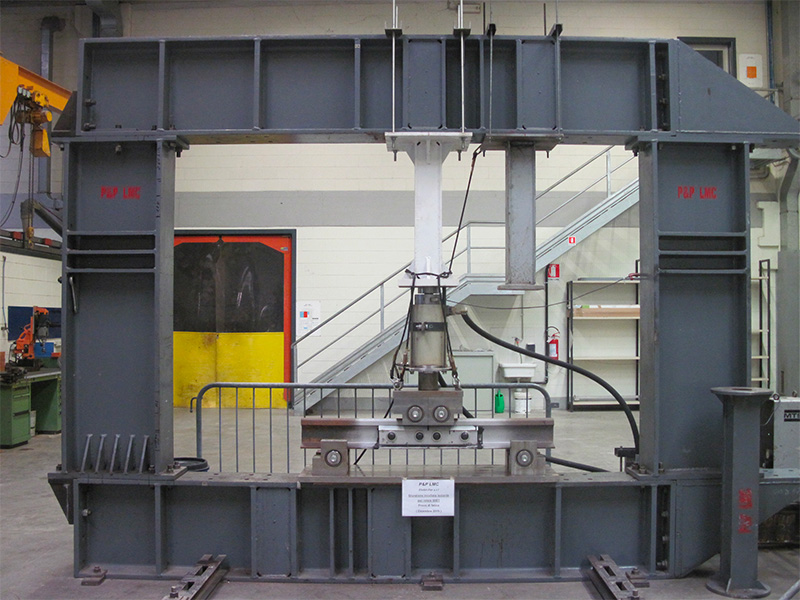

THE MECHANICAL TESTS LABORATORY

Through an in-depth analysis, the interpretation of specific standards, the study of testing methods, planning, the proposal of the best equipment and instruments subject to rigorous quality controls and regular calibration campaigns, the Laboratory guarantees continuous support to the Client for the achievement of the set objectives, with a superior quality contribution ensured by the certifications and accreditations of national and international entities.

Test laboratory accredited for carrying out mechanical and vibration tests.

Quality management system in accordance with ISO / IEC 17025: 2017 - UNI EN ISO / IEC 17025: 2018

The company is certified for quality management by a nationally and internationally recognized body.

Quality management system in accordance with ISO9001:2015

EN 13230

EN 13146

MAIN ACTIVITIES

The main testing activities are carried out in the high frequency (AF) and low frequency (BF) regime. These are accompanied by customized laboratory tests based on individual needs.

In turn, the tests are distinguished according to the methods of applying the stresses, their duration and the number of cycles to which the unit under test is subjected. Mainly, static / quasi-static tests are identified (traction, compression, characterization of static stiffness, at break, long life, conditioned, etc.), fatigue tests, dynamic tests (research of the vibratory response, characterization of dynamic stiffness, vibrations sine, random vibrations, shocks, pulses), seismic tests as well as impact tests, free fall and non-destructive tests on welds.

The proposal of the activities carried out is completed by the possibility of relying entirely on the skills of the Laboratory for the design and supply of fastening interfaces and FEM modeling.

OUR LABORATORIES

Civil Laboratory

The Materials Testing Laboratory carries out the necessary tests for the CE marking of construction materials, in accordance with the relevant harmonized product standards.

INSTRUMENT CALIBRATION

P&P provides a calibration and certification service for mechanical, electromechanical, electronic, chemical measuring instruments.

CHEMICAL LABORATORY

The main laboratory activities are: sem, earth and rocks, waste, water analysis, emissions and work environments, airborne sampling.

EXISTING BUILDINGS LABORATORY

The existing buildings laboratory supports the professional in drawing up the investigation plan, carrying out tests compliant with regulations and carrying out the restoration of the test points.

OUR SKILLS

The experience of over twenty years and the wide range of proposals of testing allows to operate in multiple sectors.

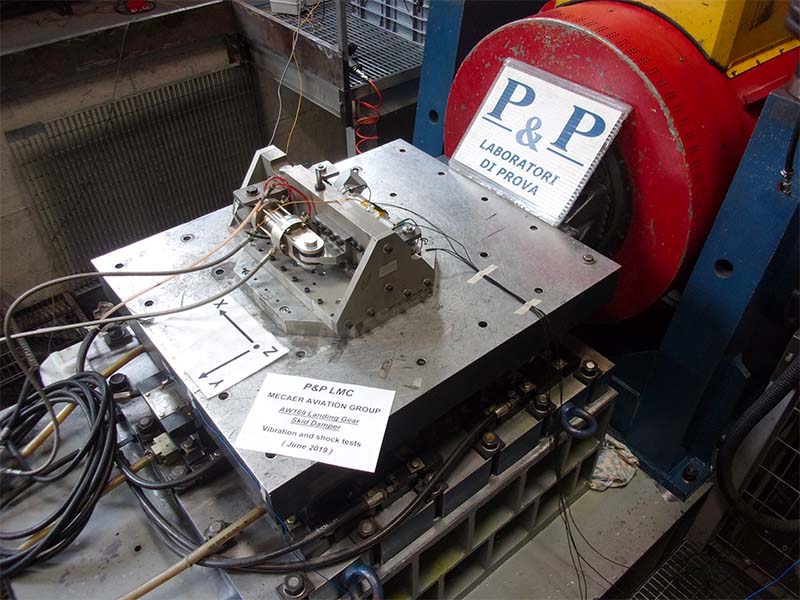

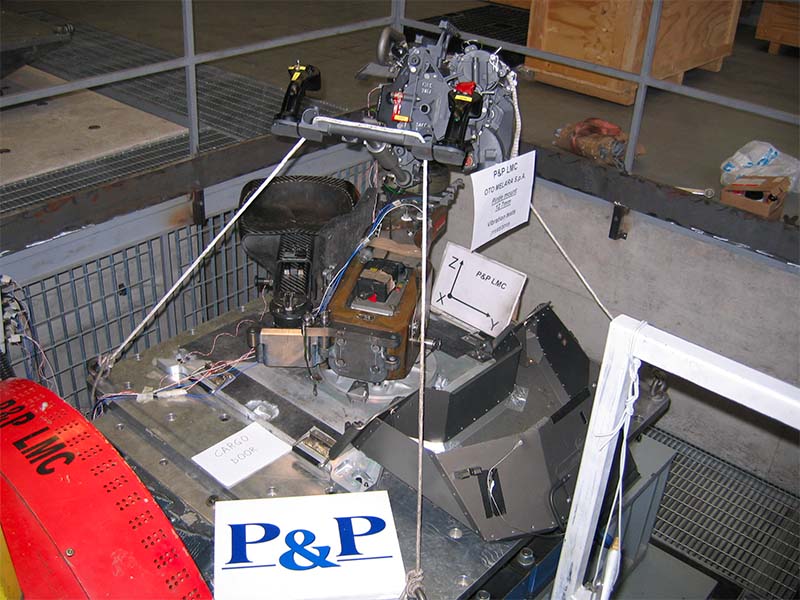

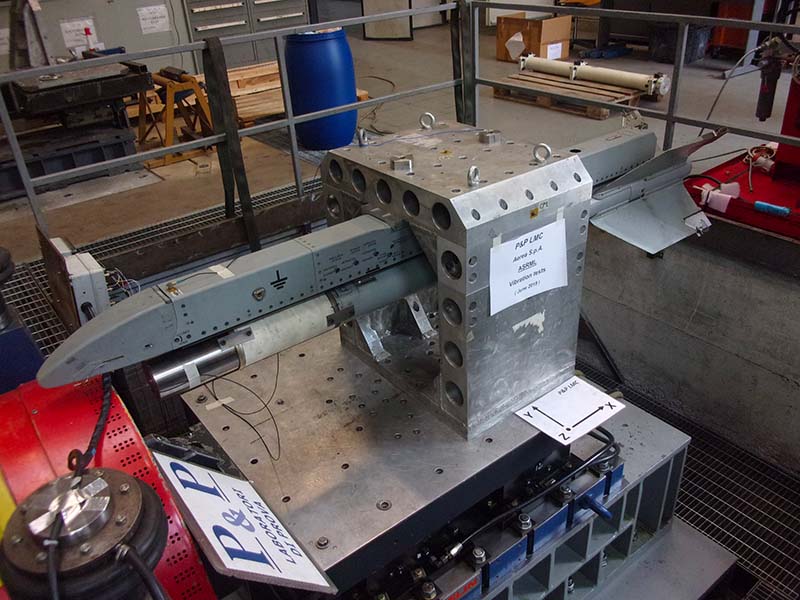

AERONAUTICS

The tests in the aeronautical field are the most severe carried out at the Laboratory.

Thanks to the know-how gained, we are able to meet the most extreme needs and the technical specifications provided by the Customer that follow strict acceptance criteria.

SPACE

Thanks to the collaborations established with international institutes and the transversal skills of the Laboratory, specific tests are carried out in the space area.

Whether mechanical or vibration tests, the ability to customize according to individual needs is the basis of the Laboratory's expertise.

ECSS-E-HB-32-26A | SSP 41172 K | IEC 60068-2-6 | IEC 60068-2-27 | IEC 60068-2-64 |

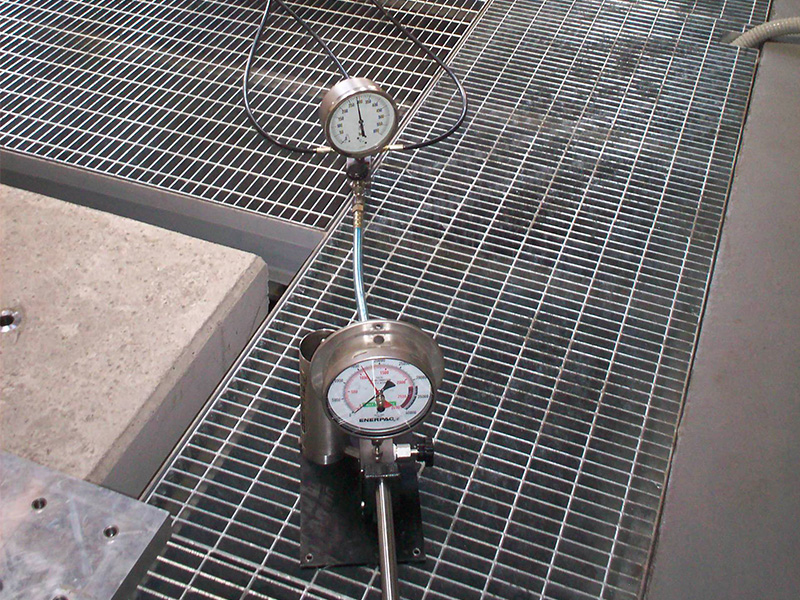

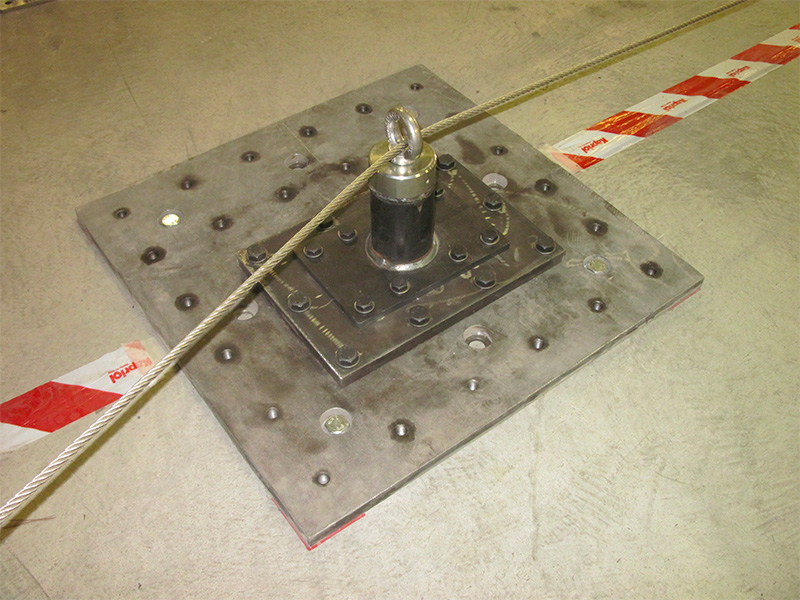

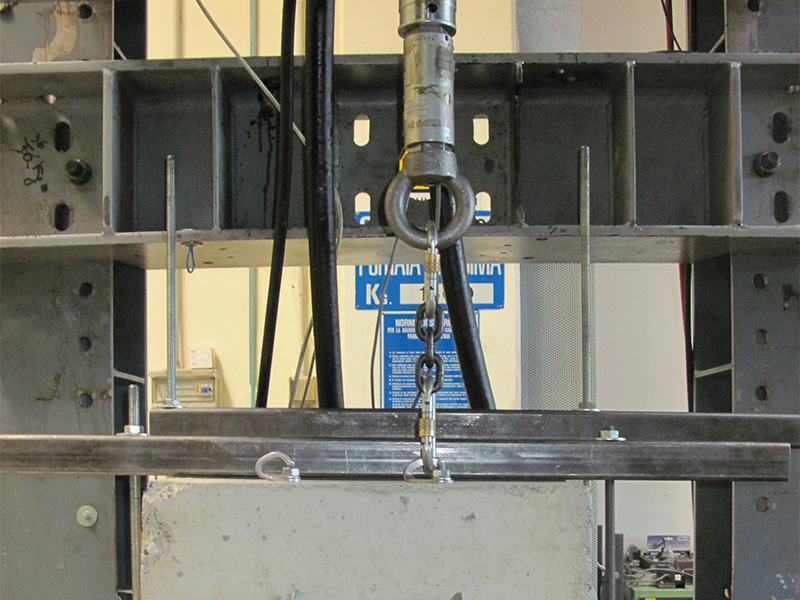

ANCHORAGES AND FALL ARREST SYSTEMS

INTENDED FOR THE CIVIL / BUILDING, MECHANICAL AND ALPINISM AREAS

Decades of experience and a test field extended over a covered area of over 1000 m2, equipped with equipment specifically designed by the Laboratory.

Tests on type A, B anchors and type C, D, E lifelines (single span, multiple and with corner) for one or more users at the same time and on anchors and hooks for mountaineering.

UNI EN 795 | UNI 11578 | UNI/CEN TS 16415 | EN 364 | EN 892 | EN 12275 | EN 959

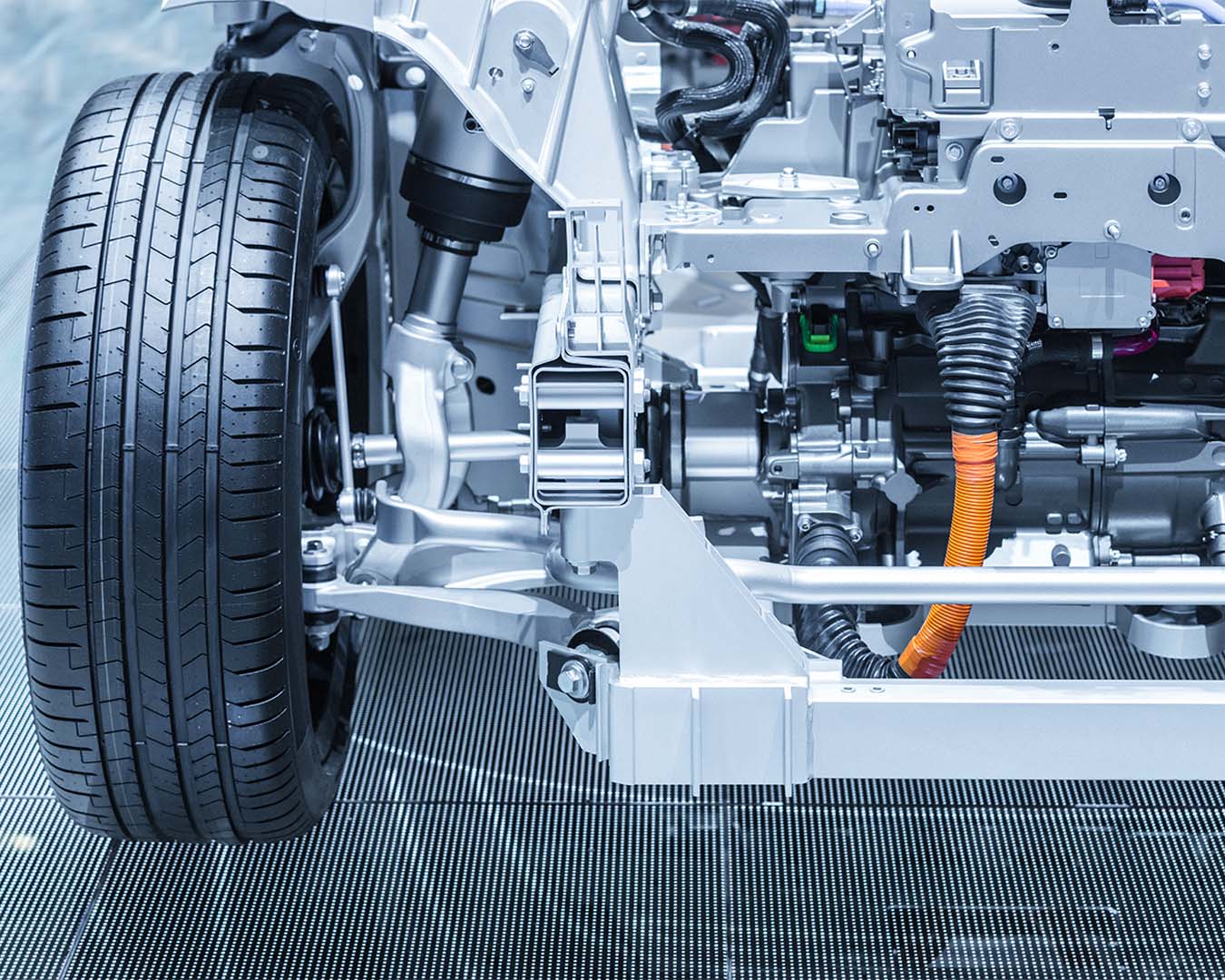

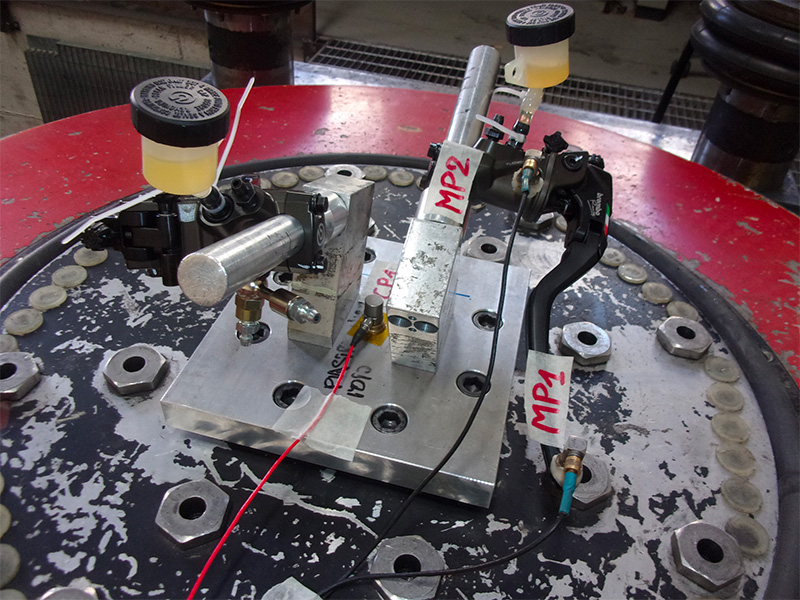

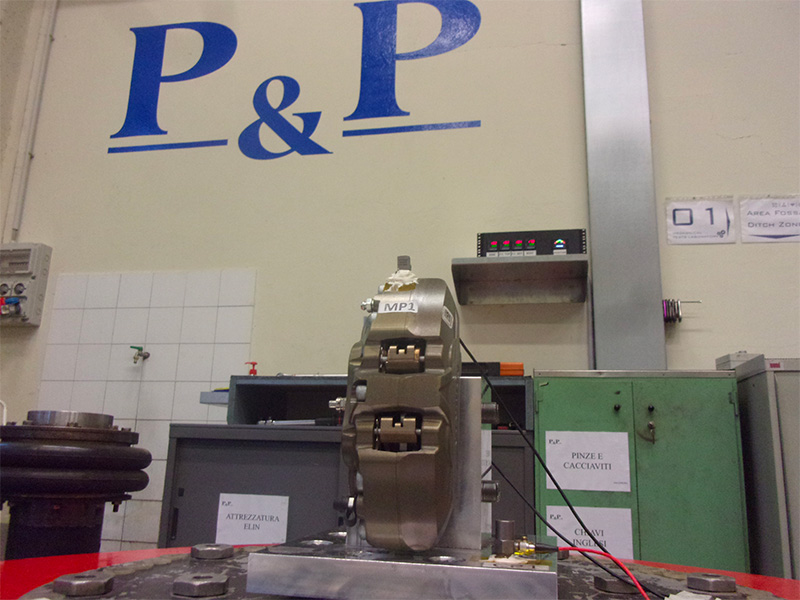

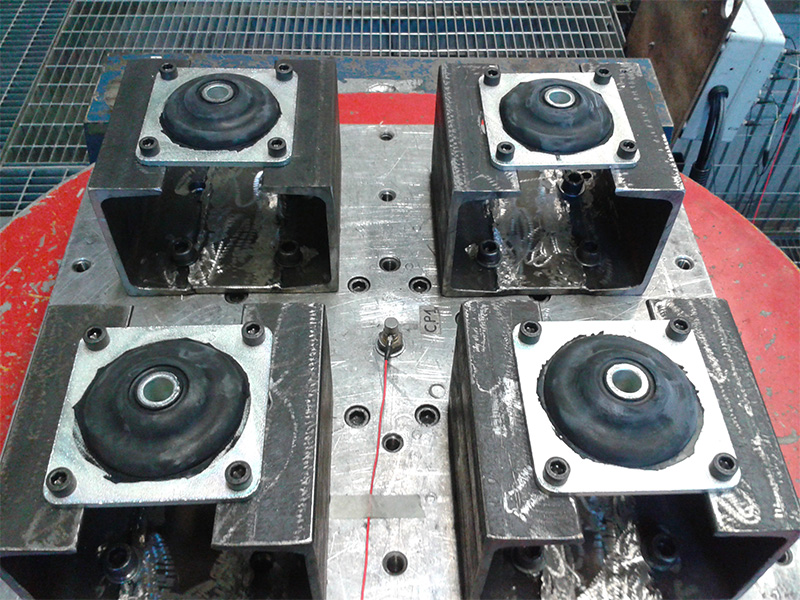

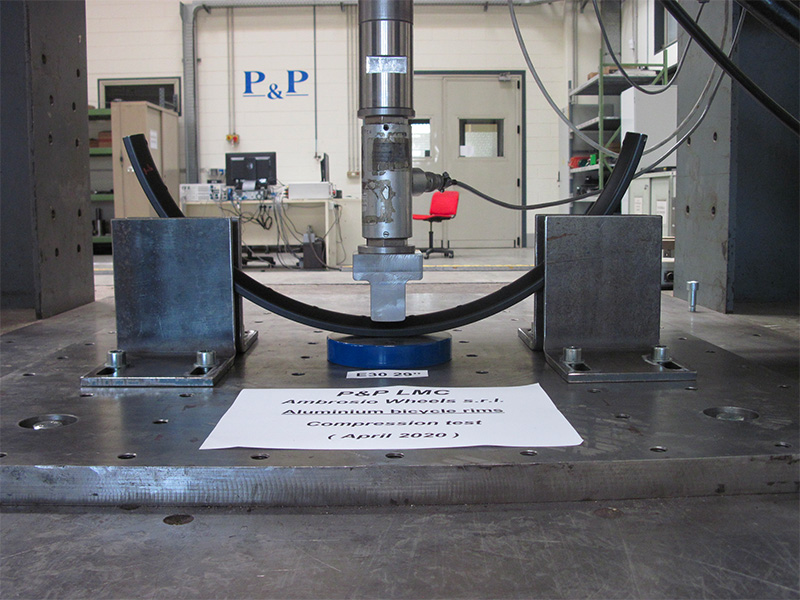

AUTOMOTIVE

The sector carries out resistance tests, research of the vibratory response, fatigue, evaluation of the stiffness of anti-vibration systems and mechanical tests on individual components.

The tests carried out concern all automotive components such as operating machines, cars, motorcycles, racing sector, cycles, etc.

IEC 60068-2-6 | IEC 60068-2-27 | IEC 60068-2-57 | IEC 60068-2-64 | IEC 60721 | FIAT

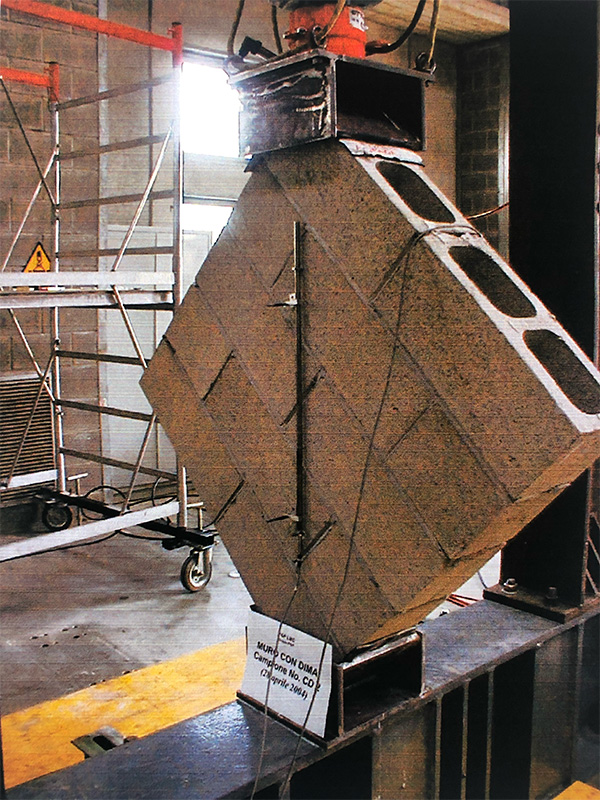

CIVIL / BUILDING

The sector that transversally also involves other departments of the company and in which the mechanical laboratory performs specific tests on both materials and components and even on mockups and scale models.

Compression, traction, extraction, shear, bending and tightening tests are carried out, in addition to qualification tests for modular elements (eg shelving).

D.M. January 17, 2018 (NTC 2018) | C. 21 January 2019, n. 7 C.S.LL.PP. | UNI EN 15512

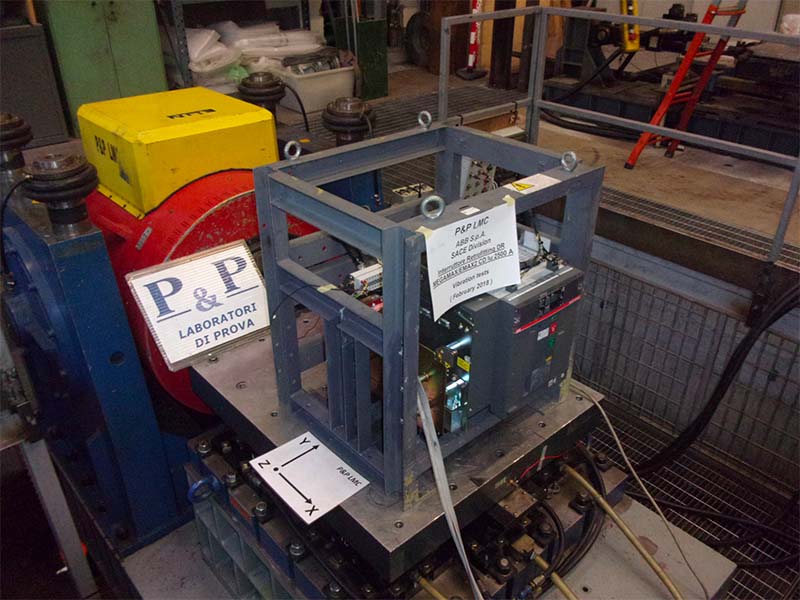

ELECTROMECHANICAL AND MECHANICAL

Electromechanical products for any use and installation are subjected to tests according to both national and international specifications and standards. The mechanical laboratory is part of this area for carrying out endurance, fatigue, performance, functionality, etc. tests. which is part of a series of tests necessary to obtain product qualification and / or verification.

The vast international regulatory assortment combined with the Laboratory's know-how guarantee the Customer the best support, as well as for the execution of the tests, also for the drafting of the test plan and the verification of any specific needs.

IEC 60068-2-6 | IEC 60068-2-27 | IEC 60068-2-57 | IEC 60068-2-64 | IEC 60721 | IEC 62281

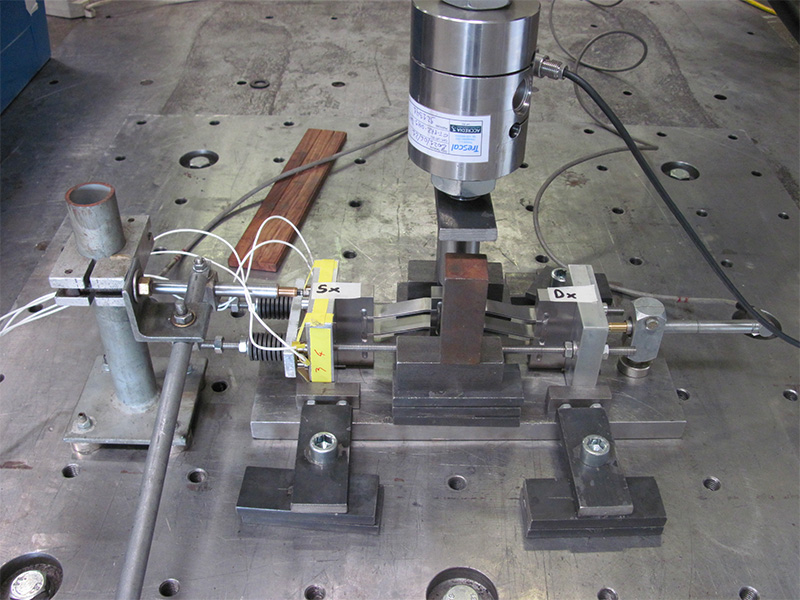

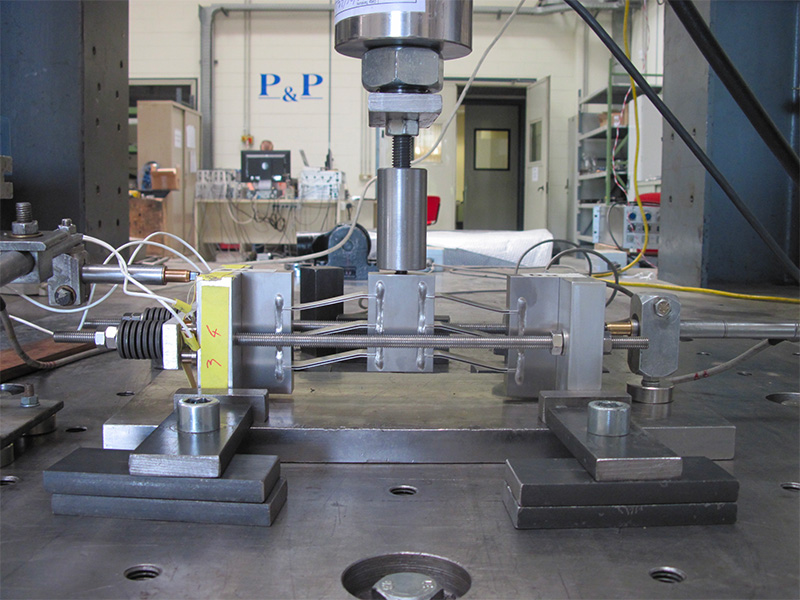

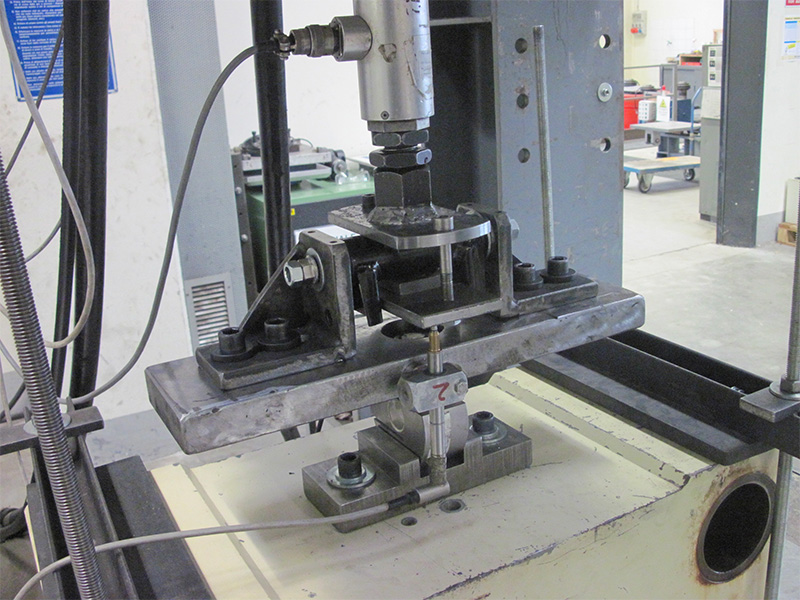

RAILWAY

For over twenty years, the Laboratory has been carrying out tests in the railway sector on armament components, body / chassis components, signaling systems, etc.

The Laboratory carries out tests on railway platforms, on rail connections, on sleepers (static, dynamic, fatigue and electrical resistance), on rails, on welds, on elastomeric materials and tests on on-board components of rolling stock, on signaling systems, etc.

The RINA Services S.p.A. qualification for the execution of homologations of sleepers and railway attachments and the accreditations for tests on rails, to which are added the accreditations for the execution of vibrational tests on components for railway use, have made the Laboratory a leader in the sector.

EN 13230 | EN 16730 | EN 27888 | RFI DTCSI SF AR 03 003 1 | RFI TCAR SF AR 03 002 | RFI TCAR SF AR 03 003 | RFI TCAR SF AR 03 008 | RFI TCAR SF AR 03 009

EN 14730 | EN 14587 | 13674 | RFI TCAR SF AR 06 006 | RFI TCAR SF AR 07 005 | RFI TCAR SF AR 07 008 | RFI TCAR ST AR 07 001

EN 17282 | UNI 5572 | UNI 10570 | UNI 11059 | RFI TCAR SF AR 05 013 A

EN 13146 | EN 13481 | ISO 9513 | CEN TR 17320

IEC 61373 | IEC 60068-2-6 | IEC 60068-2-27 | IEC 60068-2-57 | IEC 60068-2-64 | NF F 31-119 | CE 797 | CE 1302 | CE 1299 | CE 217 | D. Lgs. 57-2019

PACKAGING AND TRANSPORT

The packaging systems and the units contained therein, whether they are of considerable size and mass or more contained as in the case of pharmaceutical products, during the distribution cycle may be subject to significant mechanical stresses, such as: stacking in warehouses, shocks caused by falls , vibrations and impulsive transport loads.

Therefore, the evaluation of the resistance to harsh environmental conditions due to climatic and / or chemical effects takes place by subjecting the units with and without packaging to vibration, shock, drop, compression and transport resistance tests.

ASTM D4169 | ASTM D4728 | ASTM D6179 | ASTM D5276 | ASTM D880 | ASTM D999 | ASTM 5276 | ISO 4180 | IEC 60721 | IEC 60068-2-6 | IEC 60068-2-27 | IEC 60068-2-29 | IEC 60068-2-64 | ISTA 1H | ISTA 3B | ISTA 3E | MIL-STD-810

MILITARY

Il The Laboratory carries out specific tests in the military field on components of equipment and machines, light and heavy weapons installed in the aeronautical field on helicopters and airplanes.

Thanks to the know-how gained, we are able to meet the most extreme needs, military standards and technical specifications provided by the Customer that follow strict acceptance criteria.

MIL-STD

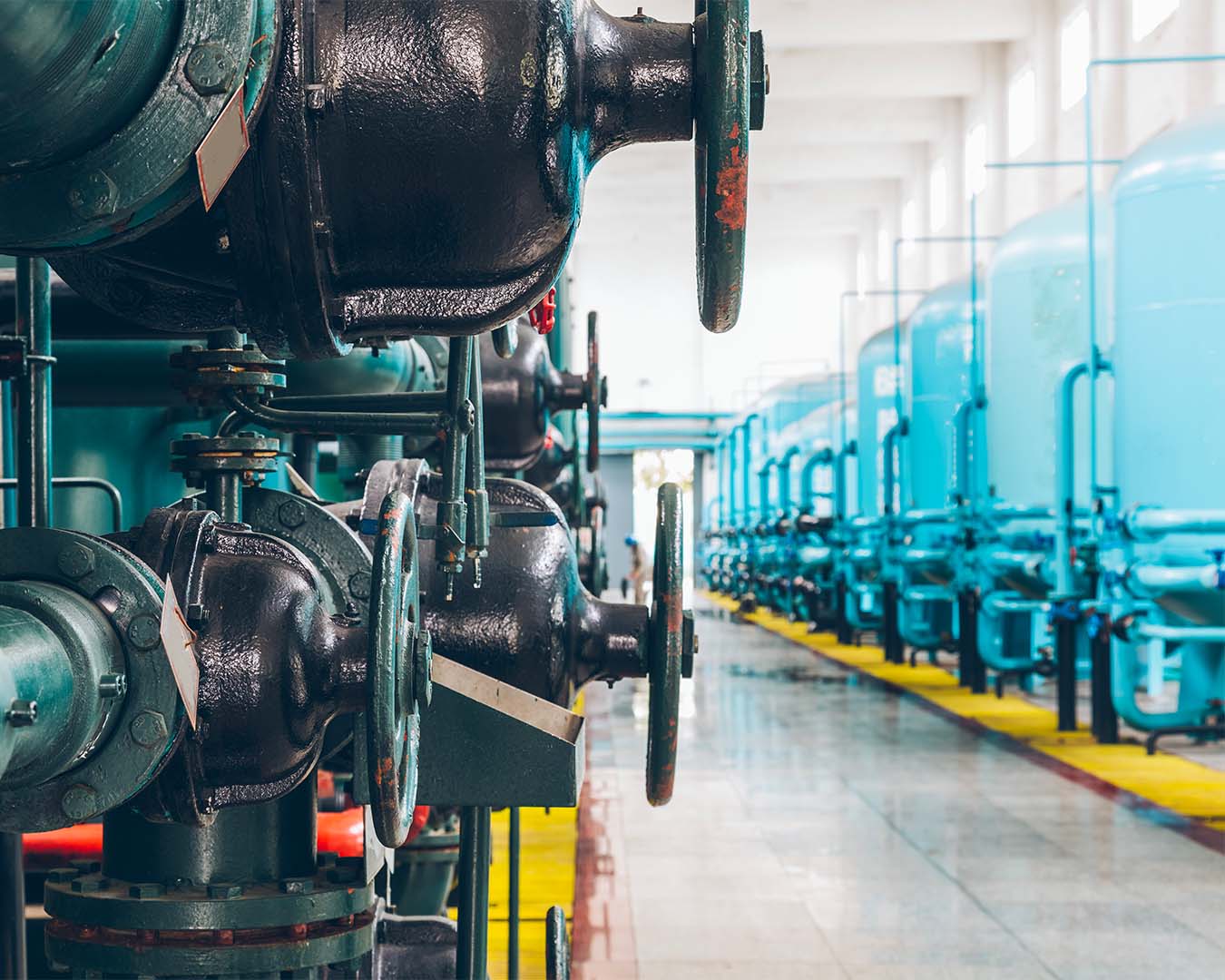

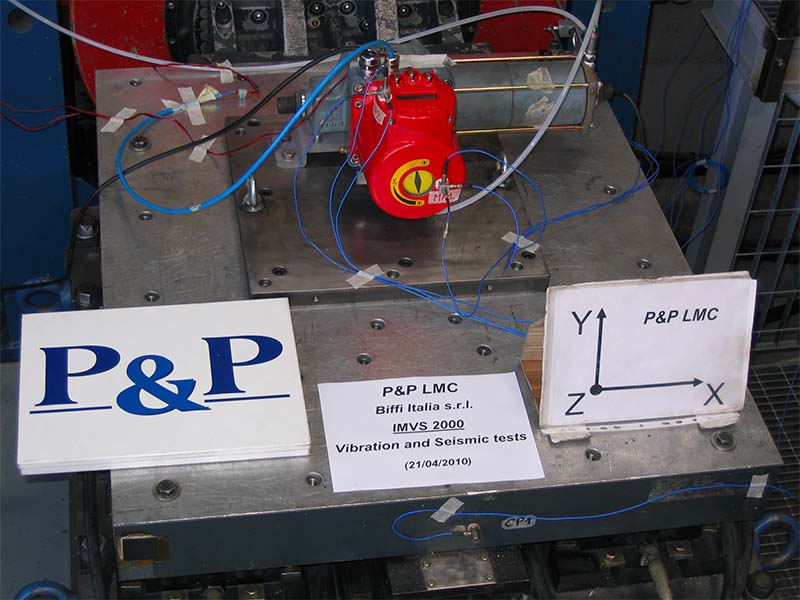

OIL AND GAS

The products used in the oil and gas sector are subjected throughout the life cycle in operation to significant mechanical stresses with exposure in environments with severe climatic and / or chemical conditions.

The tests performed are typically of resistance (endurance), fatigue, performance, functionality, etc.

The vast international regulatory assortment combined with the Laboratory's know-how guarantee the Customer the best support, as well as for the execution of the tests, also for the drafting of the test plan and the verification of any specific needs.

IEC 60068-2-6 | IEC 60068-2-27 | IEC 60068-2-57 | IEC 60068-2-64 | IEC 60721 |

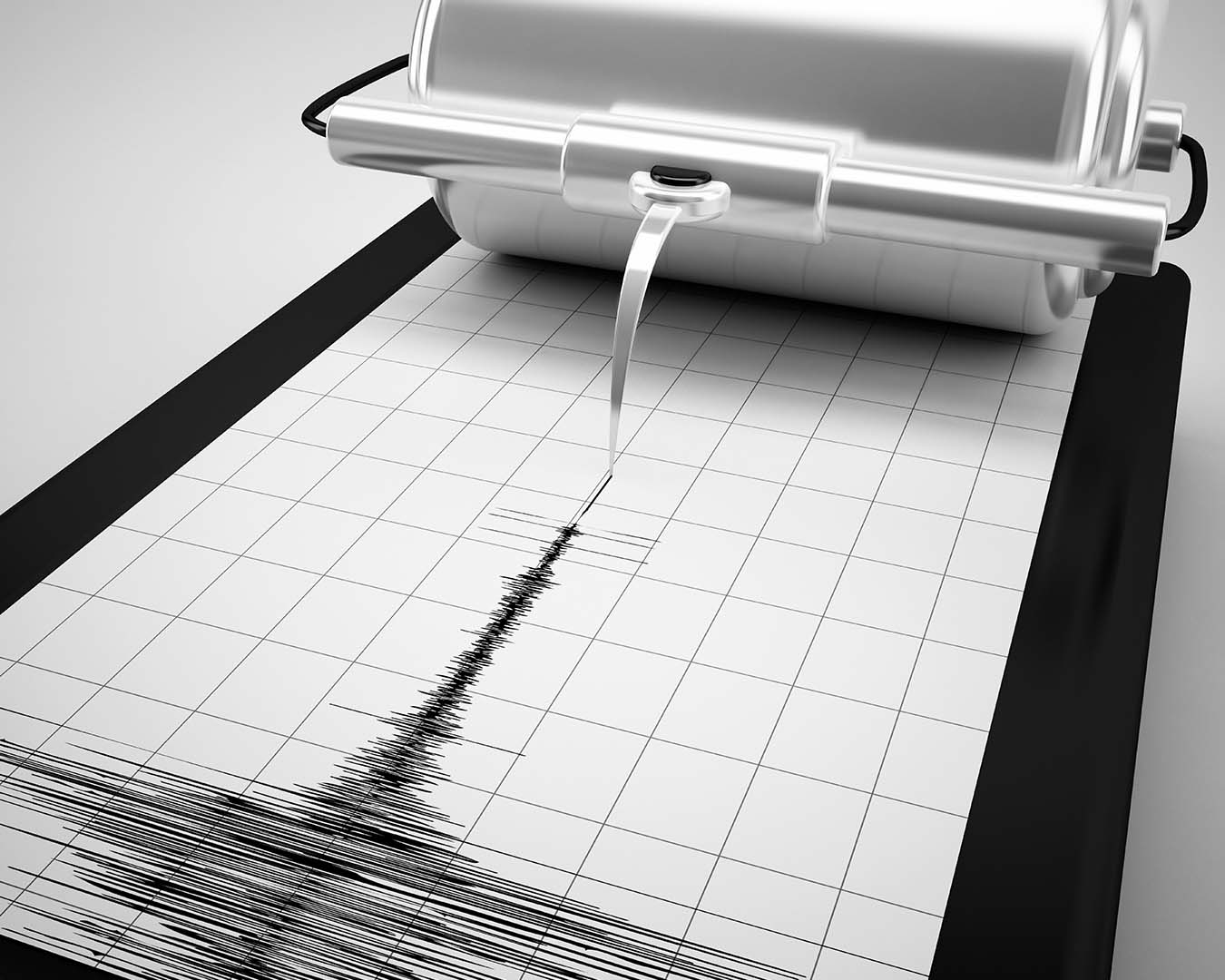

SEISMIC

The seismic qualification and verification involve most of the electromechanical components installed in every corner of the world for any use. In addition to carrying out the seismic tests, the Laboratory provides assistance in defining the acceleration spectra to be applied and summarizes each time. The time-history (accelerogram) capable of guaranteeing the achievement of the levels prescribed by the required response spectrum (RRS), such that it is enveloped by the test spectrum (TRS).

Customer assistance for these activities is essential, given the difficulties in interpreting the regulations due to their lack of homogeneity and the countless parameters to be used.

IEC 60068-2-6 | IEC 60068-2-27 | IEC 60068-2-57 | IEC 60068-2-64 | IEC 60721 | IEC 60068-3-3 | IEC 62271-207 | IEC 62271-210 | IEC 60255-21 | IEC 61587-2:2011 | GR-63-CORE | FD-NEBS-01 | FR-NEBS-EQUIP-PROTECT-01 | Enel GSCM004 | CEI 45-86 | ICC ES AC156 | ICC IBC | UBC | IEEE IEC 60980-344 | IEEE Std 693 | ETSI EN 300.019-1-3 | ETSI EN 300.019-2-3 | AS 1170.4 | NTC 2018 | E MOLTI ALTRI

TELECOMMUNICATIONS

The products used in the field of telecommunications and the like are subjected during the life cycle in operation to exposure in environments with variable climatic and / or chemical conditions, in addition to transport.

The products used in the field of telecommunications and the like are subjected during the life cycle in operation to exposure in environments with variable climatic and / or chemical conditions, in addition to transport.

The vast international regulatory assortment combined with the Laboratory's know-how guarantee the Customer the best support, as well as for the execution of the tests, also for the drafting of the test plan and the verification of any specific needs.

ETSI EN 300.019-2-2 | ETSI EN 300.019-1-3 | ETSI EN 300.019-2-3 | ETSI EN 300 019-2-4 | ETSI EN 300.019-1-4 | IEC 60068-2-6 | IEC 60068-2-27 | IEC 60068-2-29 | IEC 60068-2-32 | IEC 60068-2-57 | IEC 60068-2-64

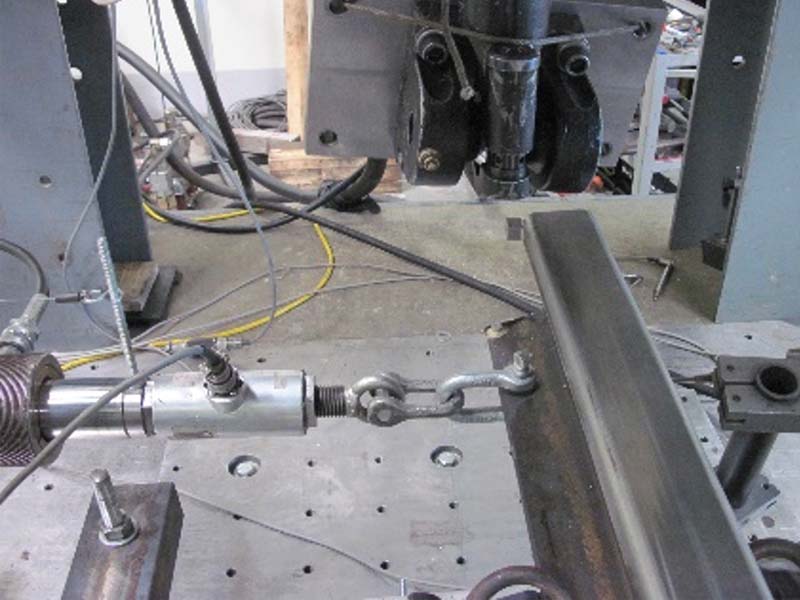

ENVIRONMENTAL AND INDUCED VIBRATIONS

For over twenty years the company has been carrying out field tests in various fields from civil, construction to mechanical and manufacturing using highly qualified equipment, instruments and personnel.

Environmental vibration tests are performed, with dynamic forcing, monitoring of induced vibrations and dynamic characterization (with strain gauges, accelerometers, transducers, etc.).

In this context, the business sectors meet, merging and giving rise to an extraordinary multisectoral experience.